CFD Consulting

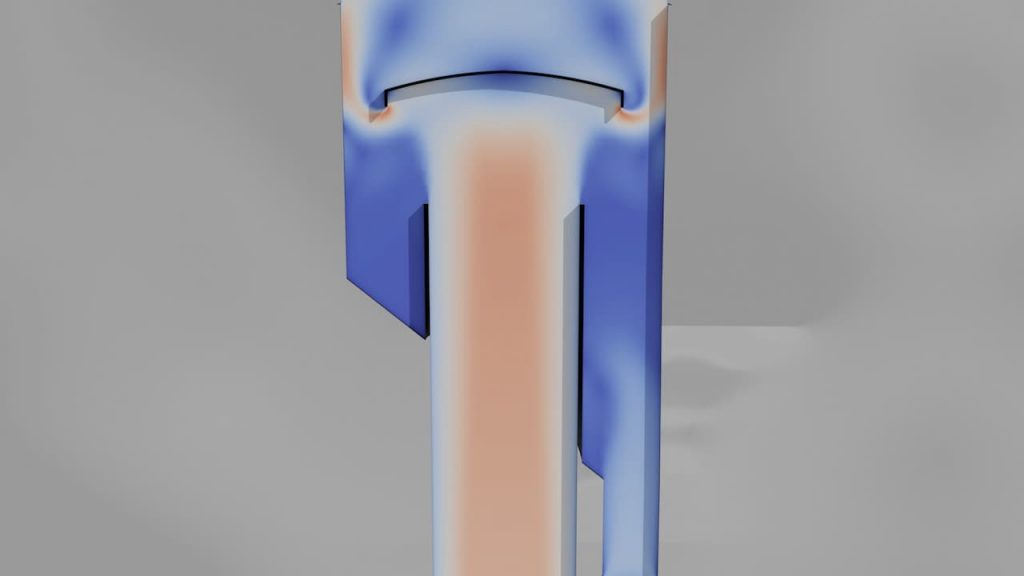

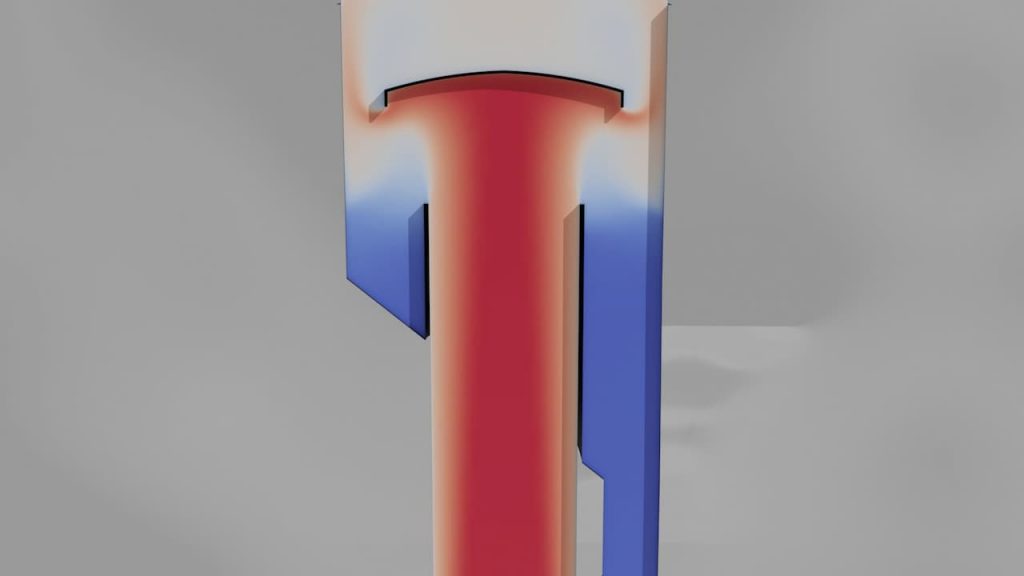

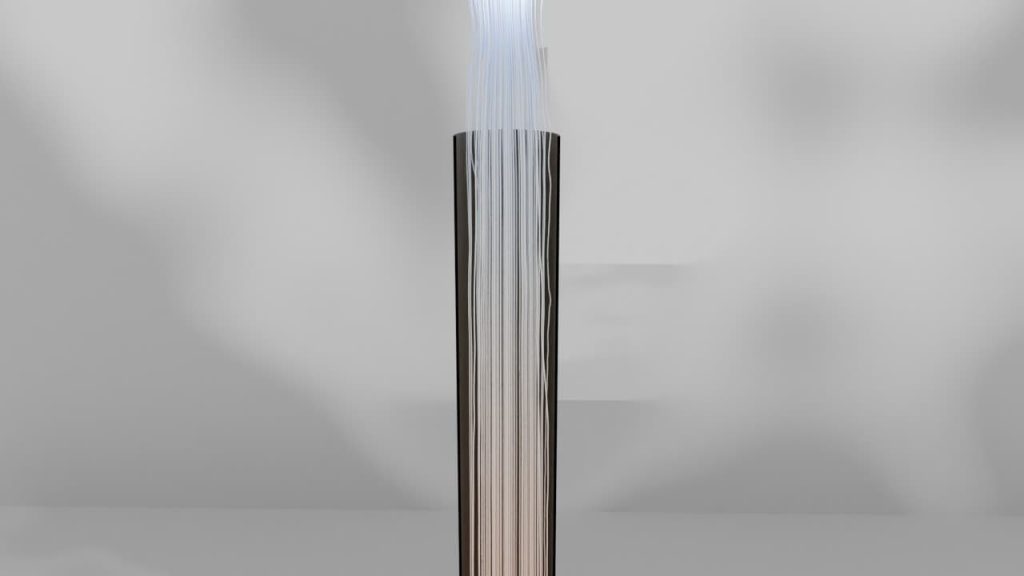

We offer you all our experience to help you in consulting projects through the use of CFD simulation.

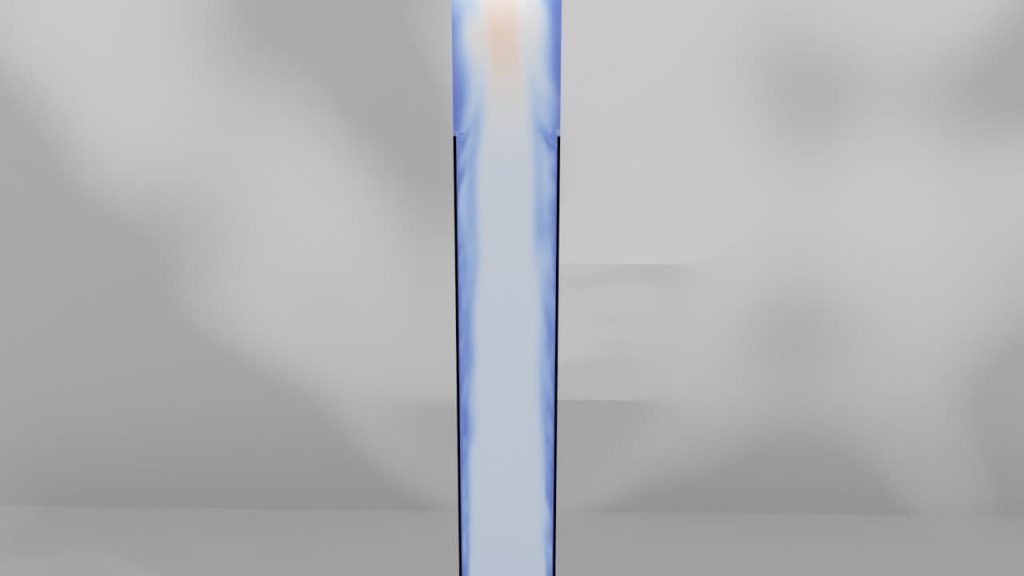

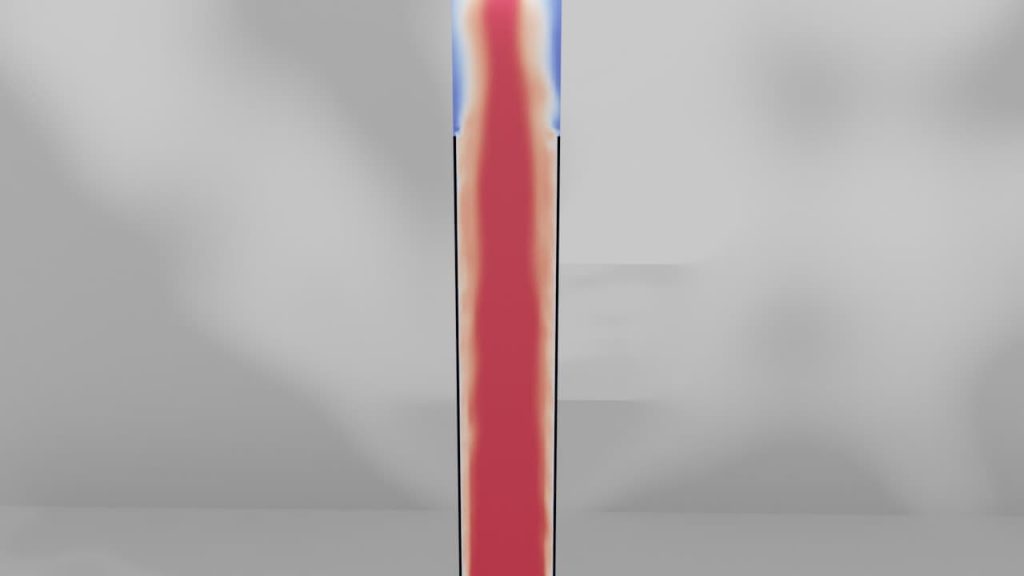

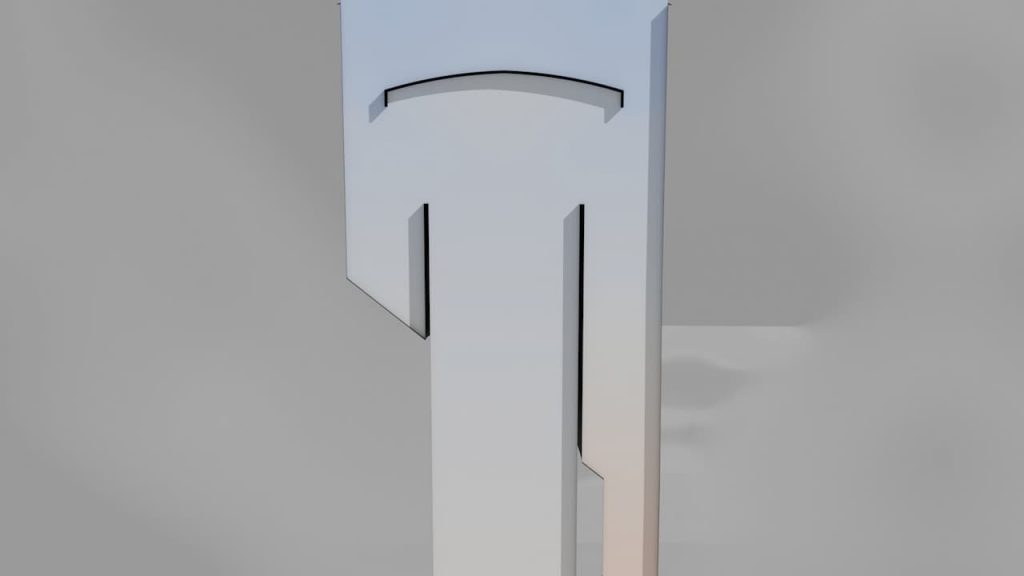

Development of CFD models

We can adapt and automate the simulation process around your case study. It has your own simulation application.