Companies involved in product design and manufacturing must go through three phases before their design is validated: design, manufacturing, and product validation.

Undoubtedly, this is a sufficiently costly process (in terms of working hours, manufacturing materials and costs derived from carrying out physical tests) to reach the last validation phase and verify that the proposed design is not adequate.

In case the product presents design flaws, we will have to go back to the initial phase and start the whole process again. Design modifications represent a huge cost for companies. Mainly in terms of time, money and product quality.

But what if we could validate the design of a prototype before it is even manufactured? This is where tools such as CFD software come into action, as it allows to check the validity of a prototype from the early stages of product development.

Therefore, we will be able not only to find the best design, but we will also be able to do it in early design phases and without the need to consume unnecessary resources in prototypes and physical tests.

The possibility of optimizing the design before moving on to the manufacturing phase brings with it a series of advantages. That’s why fluid simulation is a widely used tool in large engineering companies and is increasingly in demand by SMEs.

What is CFD simulation?

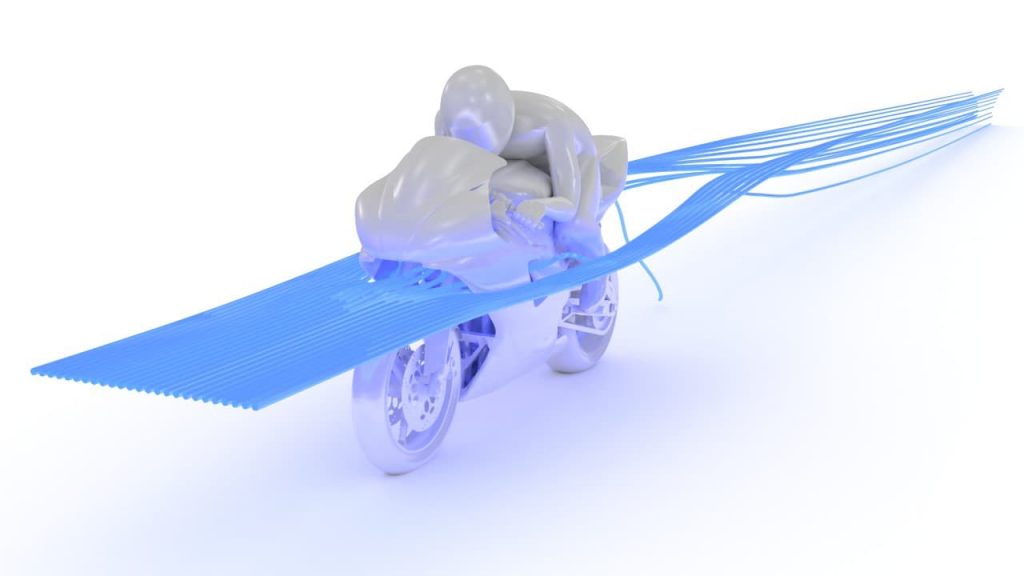

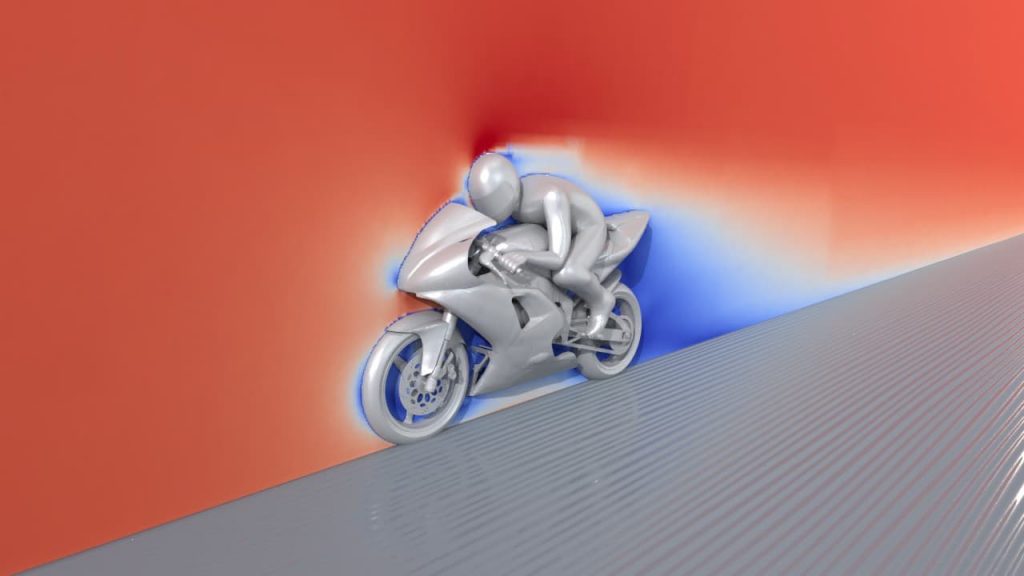

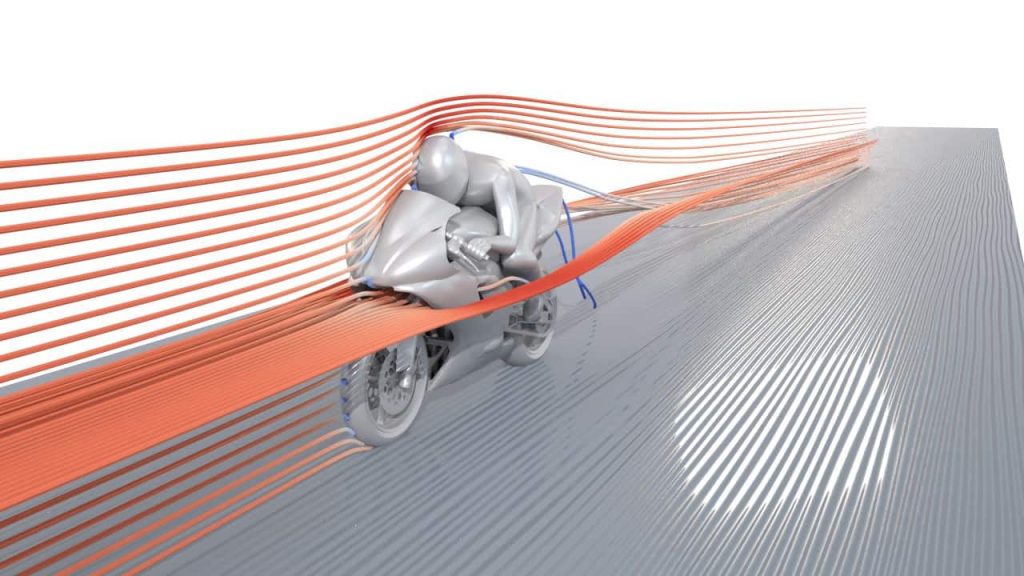

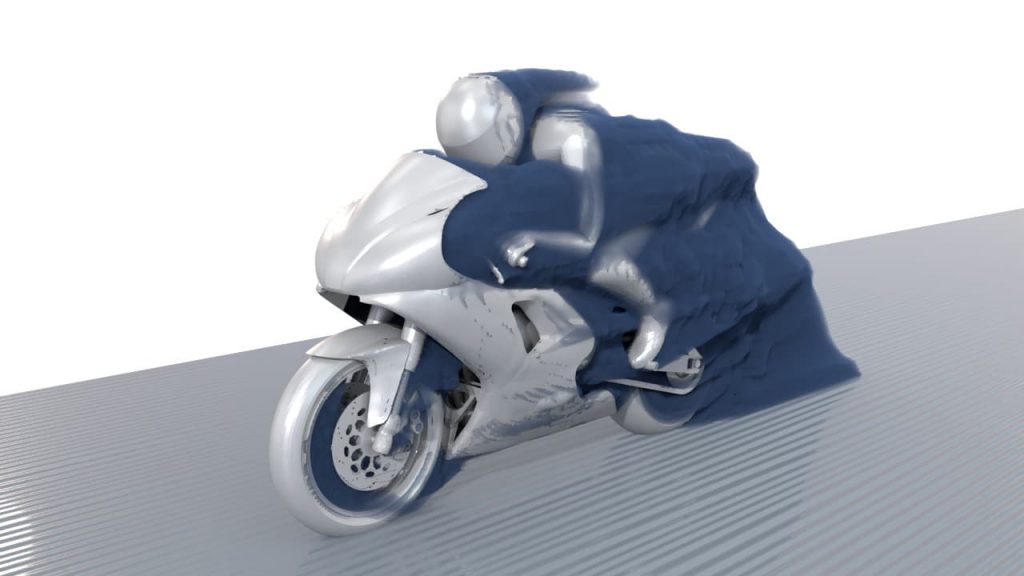

Computational fluid simulation (CFD) is a highly useful calculation and design tool used in engineering companies. Since it allows to predict the thermal and aerodynamic behavior of air (or any other fluid), through numerical calculation on a computer.

The ability to reproduce the behavior of air in a virtual environment has certain advantages in the industry. Specifically in those sectors that manufacture equipment that uses air as a working medium, as well as in companies that are dedicated to the design of vehicles. Since, for example, the resistance to the advance of a vehicle will depend on its interaction with the fluid medium in which it moves.

Advantages of CFD simulation

Below we show you some of these advantages inherent to the use of computational fluid simulation:

Design flaw detection

The possibility of testing the aerodynamic performance of any design proposal in a virtual testing environment facilitates the detection of problems in operation. In addition, we will be able to reproduce any ambient condition, so we will be able to check the performance of our product in the most extreme operating conditions.

Higher product quality

Thanks to the detection of design problems in the early stages of development, we will be able to modify our initial design proposal until it meets the required specifications. This makes it possible to optimize the design and ensure the performance of a device or vehicle, under any atmospheric condition and operating mode. Before even moving to the manufacturing phase.

Saving time and money

Derived from the above advantages, CFD simulation makes it possible to ensure, from the conceptual phases of development, the optimal design in an agile and economical way. Allocating fewer resources and involving fewer departments throughout the production process.

Sustainable product innovation

Thanks to digital prototyping. Working in a virtual simulation environment, typical of Industry 4.0, allows you to work with a digital twin and validate the performance of a product without the need to consume unnecessary resources on prototypes and physical tests.

Reduced manufacturer uncertainty

Given the high costs and uncertainty around product validation tests, the computational simulation of fluids allows us to know in advance what performance the prototype will have during those physical tests. The ability to reproduce any working condition in advance allows us to know with more certainty if the design will pass and meet the specified requirements.

Greater competitiveness for companies

We can affirm that the technology of CFD calculation, although it does not come to replace the validity of a physical validation test, it is a tool that facilitates, accelerates and reduces the costs of the entire process of design and manufacture of product. Also allowing product optimization from conceptual design phases.

This entails a greater productive capacity with a lower investment of resources or, in other words, favors the competitiveness of companies.

Technology accessible to small businesses

CFD calculation can be inaccessible and difficult to understand for the vast majority of users. For this reason, at Symula we have developed an automated cloud simulation software that favors the competitiveness of companies, thanks to the integration of cloud simulation as a tool of work.

Symula sin ser un experto.